Experimental Methods in Nanomechanics

Emerging the new field of nanoscience and nanotechnology has put an emphasis on the experimental techniques for investigating material properties and new phenomena at nanoscale. The inherently multidisciplinary nature of this field and the distinctly small characterizing scales, introduce new challenges to this field. To overcome these obstacles new devices (e.g. transmission electron microscopes and scanning probe microscopes), and novel problem-solving approaches should be pursued.

The uncertainty in the measurements, expensive experiments, as well as convoluted physics in these tiny structures force a close collaboration between the experimentalists and theoretical scientists in this field. Despite major advances in the measurement devices at nanoscale in the past decade, detailed analytical investigations still play a key role in the full understanding of the phenomena in this scale. One of the main approaches in this field, which incorporates close cooperation between experimental and theoretical scientists, is the inverse Saint-Venant's approach. In the aforementioned approach, an analytical model that captures the experimentally inaccessible states will be used for modeling a large-scale model. Then the experiments will be run at a larger scale and the results will be compared with the model to find any contradiction.

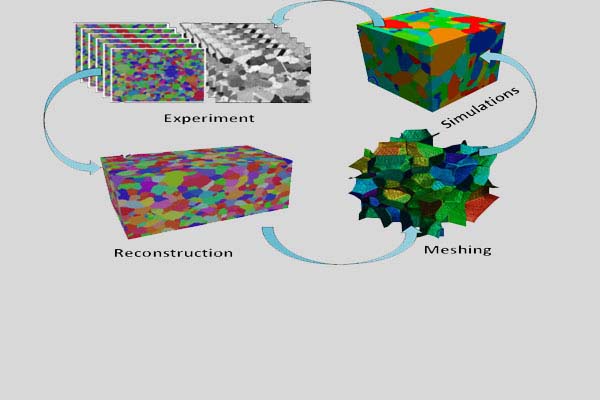

Experimentosimulation of Microstructures

Most engineering materials are not single crystals and are comprised of a collection of grains separated by grain boundaries. The overall properties of a material depend on the orientation and distribution of the grains within its microstructure. However, the microstructure of a material is strongly influenced by the kinetic processes it has undergone as well as the initial microstructure. When the fabrication of the material involves random processes, such as thermal annealing, statistical analysis is needed to obtain reliable results, which would be costly to pursue through only an experimental approach. Here, we use theoretical and computational tools to predict the effect of different kinetic processes on the final microstructure of materials. For accurate predictions, we directly import the experimentally measured initial microstructure to our simulations, which in addition to higher accuracy, allows us to automate the simulation process.

Growth of 2D Materials

The field of 2D materials emerged from the successful synthesis of Graphene, and the discovery of many other layered materials reinforced this field. The fact that the properties of 2D materials depend on their size and morphology has made them an attractive material with versatile applications, including new electronic materials and flexible electronics, biomaterials, and artificial 3D layered structures. However, the size and morphology and thus the properties of 2D materials are strong functions of the synthesis and preparation processes. Thus, precise control of the growth process to achieve the targeted structure and morphology is crucial for obtaining the desired properties. One of the promising techniques for the growth of 2D materials is the Chemical Vapor Deposition (CVD) technique. However, due to its complexity and various physics involved, designing the suitable growth condition is a challenge. Here, we utilized numerical and computational tools to better understand the growth mechanisms and find proper growth conditions without exhaustive try-and-error experiments. Our results matched well with the experiments and could predict the suitable growth conditions for the synthesis of various 2D materials such as MoS2, GaSe, and h-BN.